Introduction

In the evolving world of engineering, plumbing, and industrial infrastructure, components often go unnoticed despite their immense importance. One such unsung hero is the Tran Ny Tube—a specialized type of tubing used across different systems for a variety of functions, ranging from fluid transport and insulation to structural reinforcement and containment. While this term may not be as commonly recognized as others in the mainstream, professionals in industries like manufacturing, medical equipment, and mechanical engineering rely on it for high-performance solutions.

In this in-depth guide, we will explore what the Tran Ny Tube is, its core functionality, how it is designed, the materials commonly used for its construction, its applications across industries, how it differs from conventional tubing, installation and maintenance best practices, and important safety and environmental considerations. By the end, you’ll gain a robust understanding of why the Tran Ny Tube is an essential component in many specialized systems.

What Is Tran Ny Tube?

The term “Tran Ny Tube” refers to a category of synthetic or hybrid tubing systems specifically designed for high-performance transmission, insulation, or containment of various substances or forces, depending on the application. The name itself likely originates from the combination of “Transmission Nylon Tube” or similar variants, indicating a blend of engineering materials used for robust tasks.

Unlike conventional tubes made from simple polymers or metals, the Tran Ny Tube is crafted for resilience, precision, and multi-purpose efficiency. It is frequently used in environments where chemical resistance, flexibility, and structural integrity are all critical factors.

Construction and Materials Used

Tran Ny Tubes are manufactured using advanced polymer composites, often combining nylon, polyamide, and sometimes reinforced with fiber or synthetic braiding for added strength. The specific material composition can be tailored depending on the desired function—such as flexibility, thermal resistance, or pressure endurance.

1. Nylon-Based Core

The core of most Tran Ny Tubes is made of nylon or polyamide, which offers excellent balance between strength and flexibility. Nylon is known for its high melting point, resistance to abrasion, and minimal water absorption, making it ideal for harsh environments.

2. Multi-Layer Coating

To enhance durability, a Tran Ny Tube may feature multiple protective layers. These could include:

- Polyurethane for added elasticity and impact resistance.

- Polyvinyl chloride (PVC) for chemical protection.

- PTFE coating for non-stick and low-friction properties.

3. Braided Reinforcement

In some industrial versions, a braided mesh of synthetic fibers or even metal wire is added to withstand higher internal pressures. This enables the tube to be used in pneumatic systems or fluid conduits under stress.

Functional Purpose of Tran Ny Tube

The Tran Ny Tube is more than just a pipe or conduit; it’s a technological solution. Here are the core purposes it serves:

1. Fluid Transmission

In many systems, especially within industrial automation or automotive designs, Tran Ny Tubes are used to safely transmit fluids such as oils, coolants, or air without leakage or contamination.

2. Electrical Insulation

When applied in environments with high electrical activity, such as server rooms or embedded systems, the tubing acts as a non-conductive sleeve, offering insulation and preventing interference or short-circuiting.

3. Mechanical Support

Some Tran Ny Tubes are used in structural roles—either as support columns within composite materials or as internal reinforcement in flexible assemblies.

4. Temperature Control

With their ability to withstand high and low temperatures, these tubes serve to protect internal systems from thermal damage or to guide heat safely away from sensitive areas.

Applications Across Industries

1. Medical Industry

In medical technology, Tran Ny Tubes are utilized in devices that require clean, sterile, and durable tubing. This includes catheters, fluid transport in dialysis machines, or air hoses in CPAP devices.

2. Automotive and Aerospace

Automobiles and aircraft systems benefit from the lightweight and durable nature of Tran Ny Tubes. They’re used for fuel lines, air suspension systems, and hydraulic systems, among others.

3. Robotics and Automation

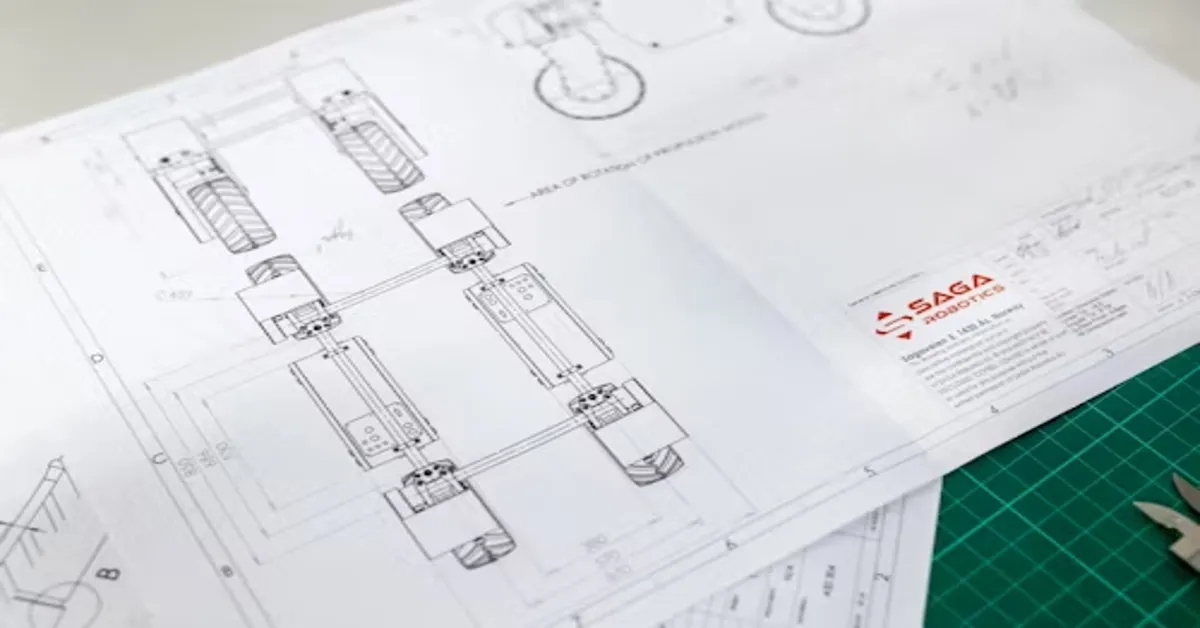

In robotic arms or CNC machines, where pneumatic actuation and cable management are essential, these tubes facilitate motion without friction, twisting, or damage to inner components.

4. Chemical and Industrial Plants

The Tran Ny Tube is ideal for use in chemical handling due to its resistance to solvents and corrosive fluids. It plays a vital role in safely channeling reactive substances in controlled environments.

5. Telecommunications

These tubes are sometimes used as protective sheaths for fiber optic cables, keeping them safe from moisture, electromagnetic interference, and mechanical stress.

Installation Guidelines

Installing a Tran Ny Tube correctly is essential to ensure its longevity and optimal function. Here’s how professionals typically handle installation:

1. Measurement and Cutting

Before installation, it’s crucial to measure the required length precisely. The tube should be cut using a sharp rotary cutter to avoid compressing or deforming the edges.

2. Secure Mounting

For fluid or air applications, the ends are typically fitted using compression fittings or quick-connect couplings. Ensure tight seals to prevent leaks.

3. Routing and Bending

Although Tran Ny Tubes are flexible, over-bending can cause internal stress points. Use guiding clips or tube supports to maintain smooth curves and avoid kinks.

4. Heat and Chemical Considerations

Install the tubing away from direct flame or corrosive surfaces unless the tube is specially designed to handle those conditions.

Maintenance and Troubleshooting

Maintaining Tran Ny Tubes involves regular inspection, cleaning, and replacing worn sections when needed. Some key steps include:

Visual Inspection

Look for signs of yellowing, cracking, bulging, or deformation—these could indicate material fatigue or chemical exposure.

Leak Testing

In fluid transmission systems, run periodic pressure tests to ensure there’s no leakage under operational stress.

Cleaning Protocols

Use non-corrosive cleaning agents compatible with the tube material to flush out internal build-up without degrading the tube.

Environmental and Safety Aspects

Tran Ny Tubes, especially those made from modern engineered plastics, pose both opportunities and responsibilities regarding environmental sustainability.

1. Material Recycling

Some versions are made from recyclable polymers and should be disposed of in accordance with local recycling programs for industrial plastics.

2. Emission and Degradation

During incineration or exposure to extreme heat, synthetic tubes can release toxic fumes, such as dioxins. Thus, careful disposal or processing is crucial.

3. Human Safety

While generally safe during use, proper handling during cutting, heating, or chemical exposure is critical. Always wear gloves and safety goggles when handling tubing in active installations.

Comparison with Other Tubing Types

| Feature | Tran Ny Tube | PVC Tube | Silicone Tube | Metal Pipe |

|---|---|---|---|---|

| Flexibility | High | Moderate | High | Low |

| Temperature Tolerance | High | Low to Moderate | High | Very High |

| Chemical Resistance | Excellent | Poor to Moderate | Moderate | Excellent |

| Cost Efficiency | Moderate | Low | High | High |

| Weight | Light | Light | Light | Heavy |

Tran Ny Tube strikes a balance between cost, performance, and durability, making it suitable for most advanced applications.

Innovations and Future Developments

As material science continues to advance, so too will the capabilities of Tran Ny Tubes. Current innovations include:

- Smart tubing with embedded sensors to detect fluid quality or pressure.

- Self-healing materials that automatically close micro-cracks.

- Biodegradable polymer variants to reduce environmental impact.

Moreover, researchers are working on nanocomposite tubes that combine the resilience of traditional materials with nanoscale enhancements for even greater strength-to-weight ratios.

Summary

Tran Ny Tube is an exceptionally versatile and essential component in modern systems, offering unique benefits in fluid dynamics, insulation, mechanical support, and more. Its applications span from high-end medical technology to heavy industrial environments, and from aviation to robotics. With proper installation, maintenance, and handling, it offers years of dependable service.

As industries continue to demand more from their materials, Tran Ny Tube represents an evolving answer to challenges in durability, flexibility, and multi-functional performance. Whether you’re an engineer, technician, or curious learner, understanding how these tubes work and how to care for them is key to maximizing their potential.

ALSO READ: Investing in Ecryptobit.com: A Comprehensive Guide to Crypto Investment

FAQs

1. What is a Tran Ny Tube used for?

A Tran Ny Tube is used in fluid transfer, pneumatic systems, insulation, and structural applications across various industries.

2. Is Tran Ny Tube safe for medical applications?

Yes, many variants of Tran Ny Tubes are made from medical-grade materials that are sterile, non-toxic, and resistant to chemical contamination.

3. How does Tran Ny Tube compare to traditional metal piping?

Tran Ny Tubes are lighter, more flexible, and often more chemically resistant than metal pipes, making them ideal for dynamic systems.

4. Can Tran Ny Tube handle high-pressure systems?

Yes, especially when reinforced with braiding or wire mesh, Tran Ny Tubes can perform under high-pressure conditions in industrial settings.

5. What materials are used to make Tran Ny Tube?

Typically, Tran Ny Tubes are made from nylon, polyamide, or polyurethane, and may include coatings or reinforcements for added performance.